I just realized one of the photos didn’t come through on my blogpost, so here it is : )

May 20

I just realized one of the photos didn’t come through on my blogpost, so here it is : )

May 20

Closing Reflection

Look back at your proposal and think about the whole Independent Study experience from then to now. Reflect on the content (what you learned) and the process (how you learned). Compose and share your thoughts in whatever form suits you best (blog post, slideshow, video, Google doc, other…) Please make sure to share it with your academic advisor, your IS advisor, and the IS Coordinator (Ms. Bessias).

Use the questions below as a menu of options. They are intended to help you get started, not to control the product.

What is your favorite thing that you learned?

I think my favorite thing I have learned is just generally how a prosthetic leg works. I’ve never considered myself to have an “engineer’s mind” or anything like that, which is why it’s so cool to be able to say that I know how a prosthesis functions and operates. When I first decided to do this project, I was a little nervous because I don’t have that natural inkling for mechanics, but I’m so glad I got to do this project and learn about this field a little more. I think it’s really helped me discover that you don’t have to be immediately amazing at engineering to try a project out; it’s a learning process.

What new questions do you have about this topic?

I would really like to learn how other body prosthetics work as well; feet, arms, hands, etc. I’d also like to know if our prototype was to be produced, what material would we make it out of? We 3D printed our prototype, so it’s made out of filament of course, but if it were to be hypothetically made for consumers, what would be the easiest and most plausible material? The goal was always to have this easily accessible, so it would need to be affordable, so maybe plastic? It’s interesting to think about.

What worked out as expected?

While Ela and I didn’t know what our prototype would be when we first approached this project, we really hoped it would end up being functional, and it was! So I guess you could say our prototype worked as expected, even though it was nothing like we first envisioned.

What was surprising/exciting/challenging?

Throughout this project, I was constantly both excited and challenged. I think a project like this inevitably comes with lots of challenges, because it’s impossible to know exactly where you’re going to go when you start out. Ela and I had originally imagined we’d make a prosthesis, only to find out that wouldn’t really be plausible if we wanted to make something accessible to all. We constantly had to adapt and re-design, and re-envision this whole process. We went from a prosthesis, to a custom joint, to a camshaft, and eventually to a piston and ball joint. Crazy stuff, and it was challenging to have to keep adjusting, but I think that made it exciting as well. We didn’t know exactly what we were going into, which kept us on our toes, and kept the whole process open. It really felt like the sky was the limit at times, which was such a cool feeling.

What did you learn about your learning process?

I’m learning time and time again how much the learning process changes. Looking back at our initial plan for this project, it was really different. Our weekly calendar is WAY off, it’s funny to think that we thought we could really map this project out down to the week. The truth couldn’t be more different, because you never know where the learning process will take you- even though we ended up going somewhere different then we thought, it was still a fantastic journey. The learning process is never going to be set in stone, and that’s okay!

What advice would you give to future Independent Study students or their advisors?

First, I’d say don’t be scared to step out of your comfort zone. I know it can be scary, but it’s so important to try. I’ve always thought of myself as a humanities kid, which was why I was a little worried about this project, and it ended up being amazing. Just because you don’t think you’re initially good at something, doesn’t mean it has to stay that way forever- try it! Do something new, and expand your horizons; it could turn out better that you would have thought. Second, if you’re considering whether to take an IS, I’d say go for it! When we were first trying to do this project, and our teachers were trying to figure out whether it would be too much for us, it was a difficult choice to make. It’s hard to balance something you want to do with knowing that you don’t want to take on too much, but I’m so glad we got to do this project. It challenged me and excited me, and it was really an invaluable experience, to get to learn how to study something independently, without a predetermined course of action.

May 19

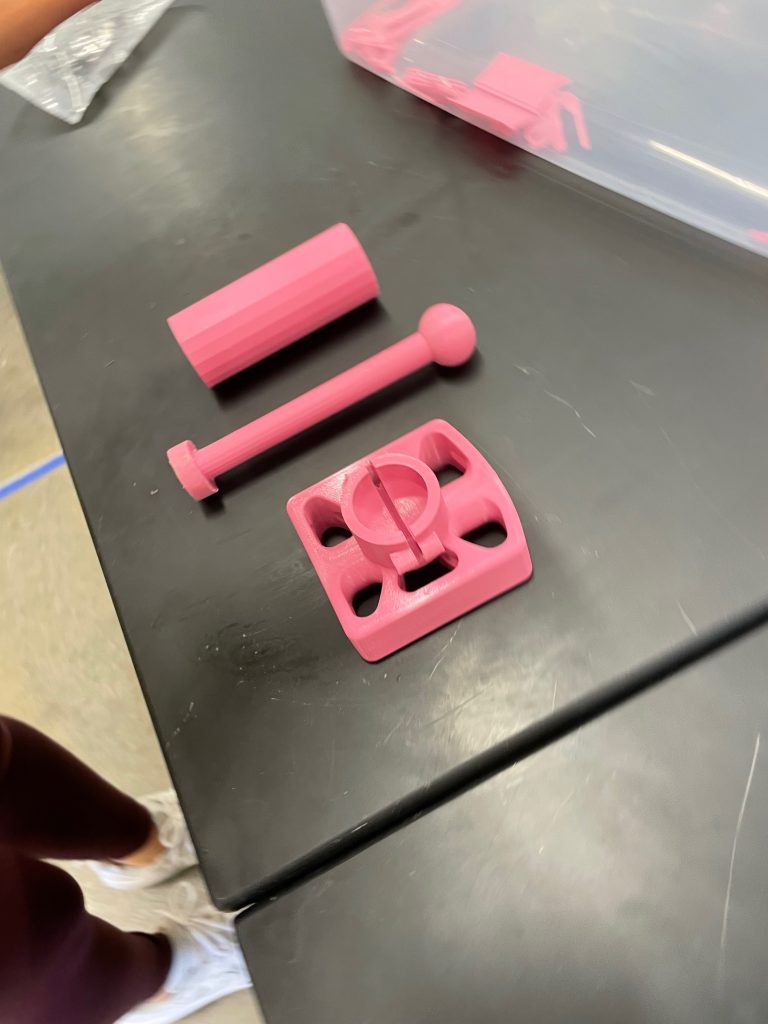

It’s done and it works everyone! I can’t believe it, it’s so amazing to see the culmination of research, interviews, design and just overall hard work. The print finished and we tried it out on the bike in the gym, and it worked! We put a spring inside the tube to help the piston move up and down, and it turned linear motion into rotational motion, which is so crazy! Ela and I will be making a video talking about everything; our process, how it works, the feelings we had while completing this project, so be on the lookout for that! Thanks for sticking around, and be sure to watch the video, it’ll be an in-depth explanation of everything.

May 11

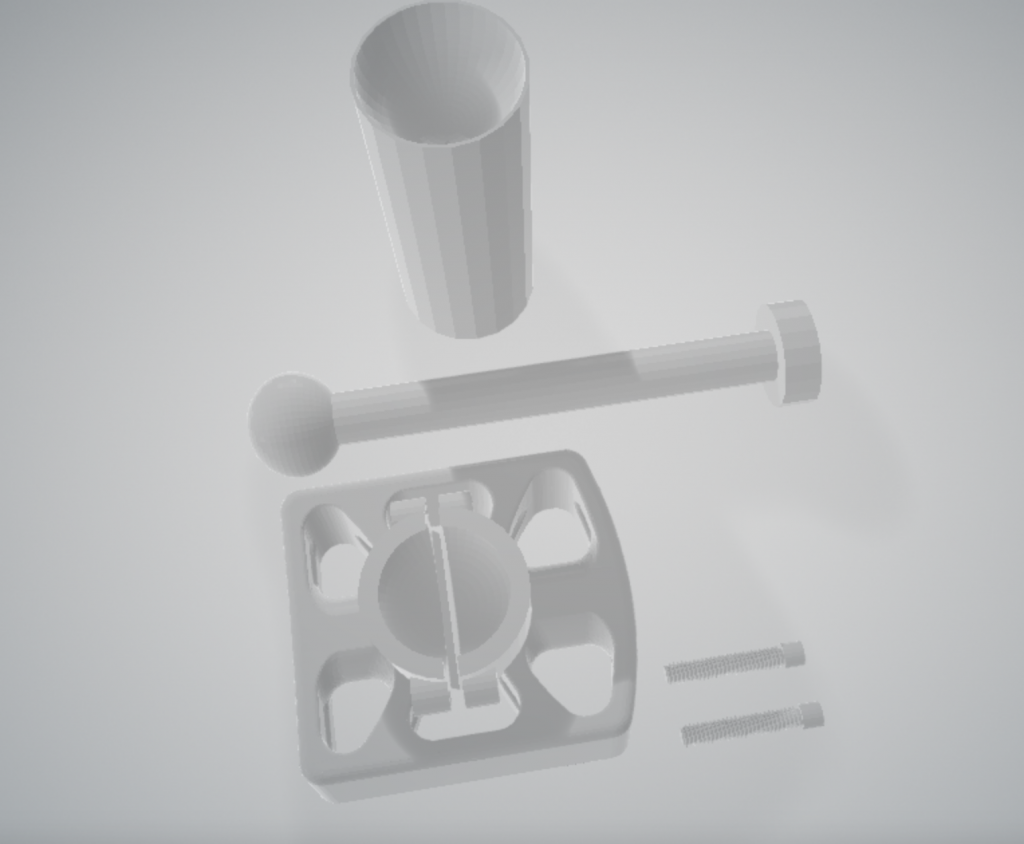

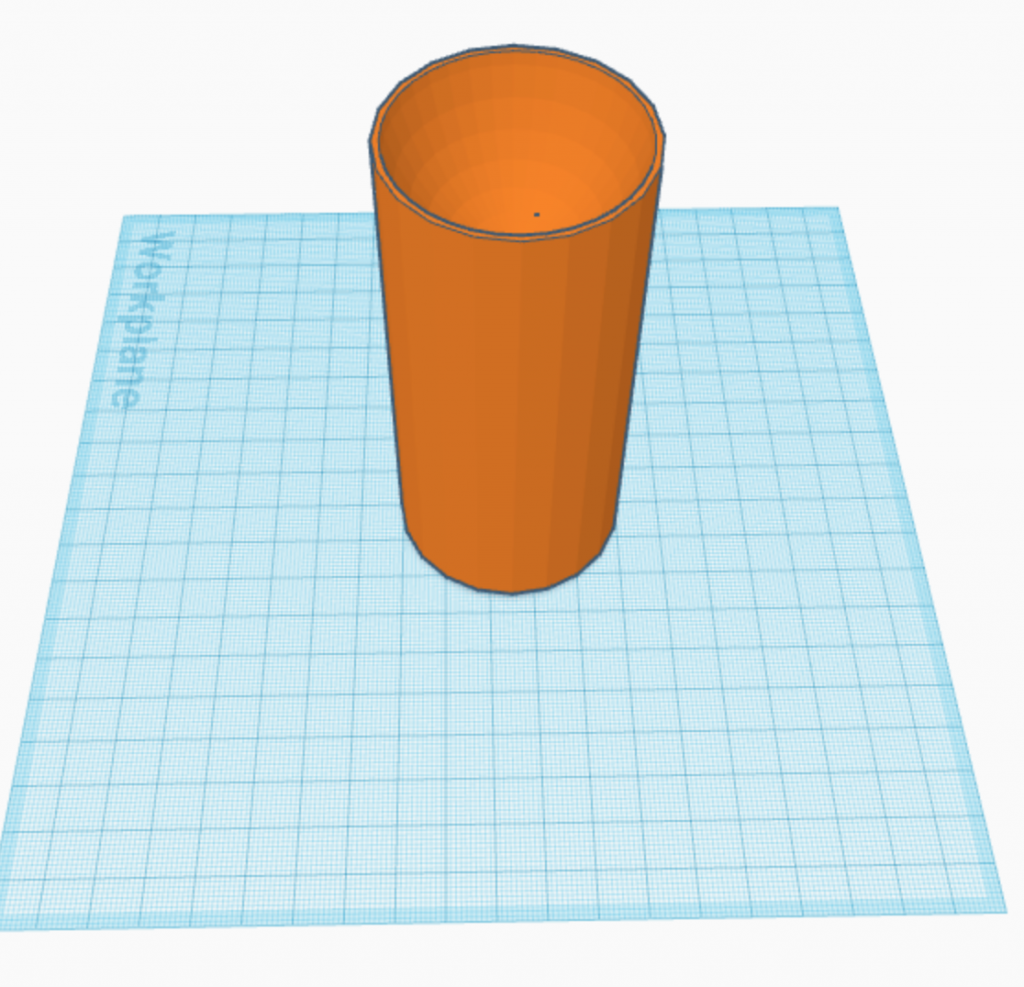

YOU GUYS YOU GUYS ITS PRINTING! Okay let me calm down and catch you up. SO. Since my last post, we designed the final design on tinkercad (here it is below). There’s a hollow cylinder with a dome carved into to it, which will attach to the leg stump, and a piston will go up and down in the cylinder, making it airtight. At the end of the piston will be a ball, which will go into the ball joint connected to the pedal, turning the linear motion into rotational motion. Here’s the design!

AND NOW ITS PRINTING! I still can’t believe it, it doesn’t feel real yet, but as soon as it’s finished it probably will. I’m so excited, I’ve never 3D printed something yet, and it’s so cool to see the culmination of a long semesters work (fingers crossed that it will work!). I’ll update you guys as soon as it’s finished, this is what it looks like right now

Apr 29

Here’s the plan so far: connected to the stump will be a hollow tube with a dome to connect to the leg. Inside the hollow tube will be a piston rod with a ball at the end of it, which will into a ball joint connected to the pedal. This may change if we want to pursue our egg shaped idea, but based on what Emmet helped me design on Tinkercad, this may be the best course of action. The leg’s linear motion will be turned into rotational motion by the tube with the piston rod, and the ball joint will transfer that energy into the pedal, and propel it forward. Fun!

Apr 26

Hey everyone! Sorry for the sparse blog posts, it’s hard to figure out what to post during the design stage of this project. I am currently working on tinkercad to design parts of our “cam shaft”, which we will later 3D print. Earlier today, I worked on designing a hollow cylinder with a semi-sphere, to fit with the stump (HUGE shoutout to Emmet Christian for teaching me how to use tinkercad and bring what we visualized to the program). Later, we’ll print the egg shaped object that will push the pedal forward, and make them a cohesive item. We then need to work on securing the device to the stump itself, most likely through a strap, like I talked about earlier in these posts. That’s it for now, thanks for reading! I’ll be sure to update more as we continue to work our way through the process : )

Apr 04

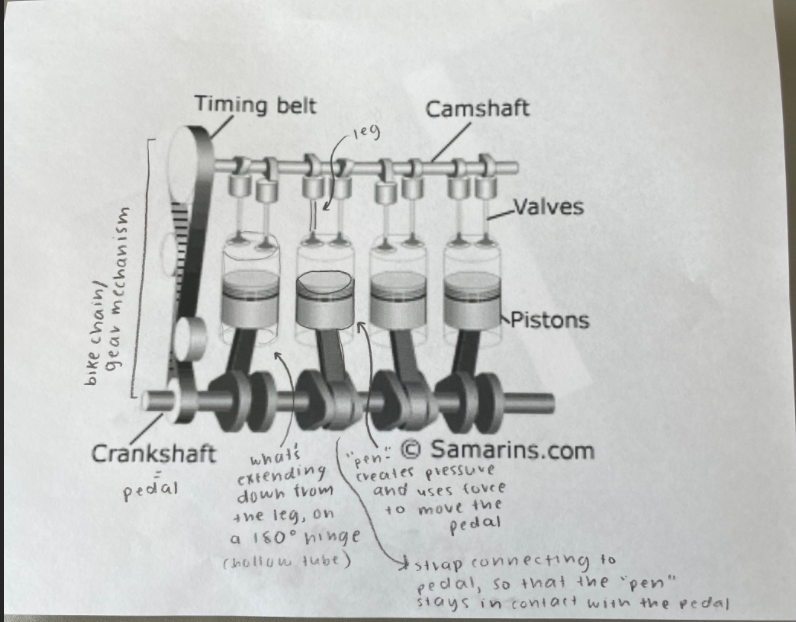

Hi guys! We got an image of an engine from google and applied the different parts to our scenario

Mar 18

Mar 18

Yesterday we met with Ms. Starling and just talked more about our ideas (very exciting!!) We do want to make an upside down CamShaft that can connect to the socket of a prosthesis. Ela and I were worried about the CamShaft not being long enough to reach the pedals, but the egg-like shape at the bottom will fix that. If the round-ish object at the end of the CamShaft was a perfect circle, it wouldn’t work, because then it wouldn’t be able to touch the pedal at all times. With a more oval shape it will, which is so great! Now we’re going to learn more about CamShafts so we can start to actually design!!

Mar 04

Hi!! So much has happened since I last wrote, I’m so excited. So Ela and I began the brainstorming process, which was very interesting to say the least. Some of my ideas were “interesting” but I was told by Devin Hubbard, who met with Ela and I earlier in the month, to write down whatever popped into my head, so I did. I had several ideas; a rod that attaches the pedal to a hand, a propeller attached to pedal, an INVERSE UNICYCLE , where you have two wheels and one pedal… Anyways, we met with Dr. Saul, who advised us to go in a CamShaft route, which Ela and I both loved. Basically, you want rotational motion, which is what the bike pedal exerts, but a CamShaft helps you achieve that rotational motion through linear motion, which simplifies everything- this is a CamShaft, image courtesy of the one and only wikipedia.

Then earlier today I met with Dr. Aaron Fleming and Brendan Driscoll, a grad student who actually has an AK prosthesis and has biked before. The meeting was insanely helpful. Dr. Fleming pointed out that many people in LDCs have prosthetic sockets, they just don’t fit right. Brendan, and most people in LDCs wear something like this https://cdn.shopify.com/s/files/1/0824/6797/products/syncor-tes-belt-with-cut-out-above-knee-suspension-belt-TES-300_grande.jpg?v=1564946182 that connects to a belt to stabilize the socket and keep it from falling off. The other thing that Brendan told us was that getting on the bike was one of the most difficult parts of riding the bike itself, which is something we need to consider. Dr. Fleming was also wondering if we might want to connect the CamShaft to the socket itself rather than the stump. All in all, we got such great feedback from so many amazing people we interviewed (thank you so much!!!) and will be implementing their feedback and advise in our future steps. Yay!